As a reliable testing laboratory, we also routinely offer our customers seed and blister content analyses.

The typical blister content analysis is performed using gas chromatography, mass spectroscopy and/or Raman spectroscopy and covers the gases H2, Ar, O2, N2, CO2, SO2, CO, COS, H2S, CH4 as well as H2O.

In this context, it is particularly important that all gases, explicitly including all of the above-mentioned sulphur modifications, as well as the pressure, are analysed during the blister content analysis, as this is the only way to obtain a meaningful interpretation of the origin.

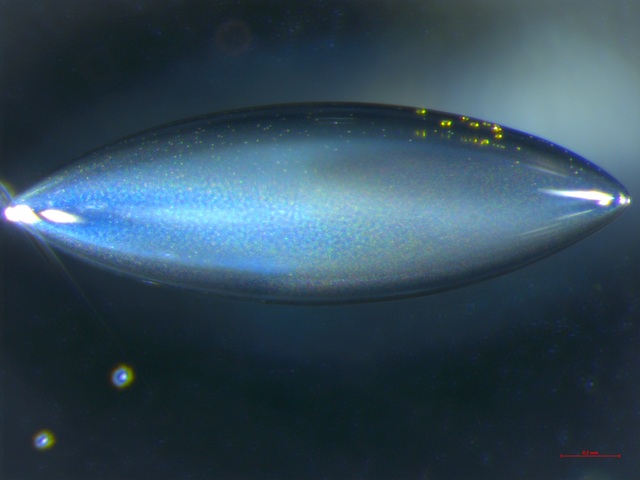

In addition to gas content analysis, we also use microscopy to examine the inner surface (e.g. crystals or droplets) as well as the shape, size and location of the seeds or blisters, enabling us to provide tips on how to avoid these gas inclusions in the future.

If other abnormalities such as streaks or particles are found in the surrounding area of the blisters and seeds, we also carry out an SEM-EDX examination in order to obtain additional information about the cause of the blister formation.

We interpret the results based on the macroscopic and microscopic examinations we have carried out, the results of the blister content determination and the information received from the client, such as melting tank and raw material parameters and cullet qualities. This enables us to interpret the origin of the blisters formation so that we can develop and communicate suggestions on how to modify the melt to prevent blister formation in the future.

A typical blister with crystalline deposits (e.g. sodium sulphate) and droplets (e.g. sulphur)

From time to time, we analyse very special blisters, known as vacuum blister (also called vacuoles), which are blisters without crystalline or gaseous content. They occur when the glass cools too quickly during production. These special blisters are not present during the forming process, but only develop afterwards. Physically and chemically dissolved gases in the glass have no way (high viscosity, low temperature, no time) to diffuse into this cavity. These blisters can also no longer float up (viscosity > log 10^7.6). Our analyses revealed no crystals and no gas content, so they are empty.

Another special feature of the vacuoles is that they disappear immediately when the glass is reheated to a temperature of approx. 650 °C – 680 °C. One of our IGR customers has provided us with a video in which this process can be observed in detail.

How? When watching the video, pay attention to the two bright spots on the left and right. The first blister (left) disappears at second 16 , the second (right) is no longer visible at second 28.

If you have any questions, please do not hesitate to contact us.

The IGR team looks forward to working with you and your company in the future.